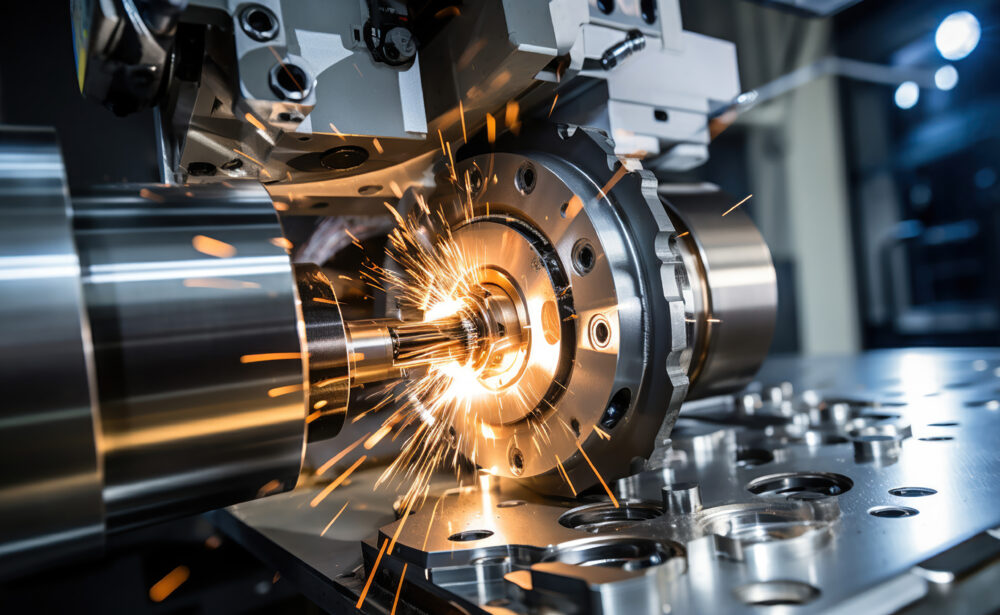

Our skilled welding and assembly services ensure every component fits, functions, and lasts — forming the structural core of your metal product.

- MIG, TIG, and spot welding for different applications

- Certified welders ensure strength and consistency

- Precision fixtures used for accurate alignment

- Assembly of fabricated and outsourced components

- Load-bearing and structural welds for industrial use

- Clean and smooth weld finishes for aesthetics

- Rigorous inspection of welded joints

- Final mechanical and functional testing during assembly

We go beyond fabrication — delivering fully welded, assembled, and functionally verified products ready for installation or integration.

Weld Strength Pass Rate

Assemblies Completed Monthly

Combined Welding Experience

Frequently asked questions

Clients often ask how we ensure strength, safety, and assembly accuracy — here’s what you need to know.

We offer MIG, TIG, and spot welding depending on the material type, product thickness, and structural requirements.

Yes, we provide integrated assembly for metal parts along with non-metal components like insulation panels, gaskets, and brackets.

Each weld is inspected for strength, penetration, and visual quality using both manual checks and non-destructive testing techniques when needed.