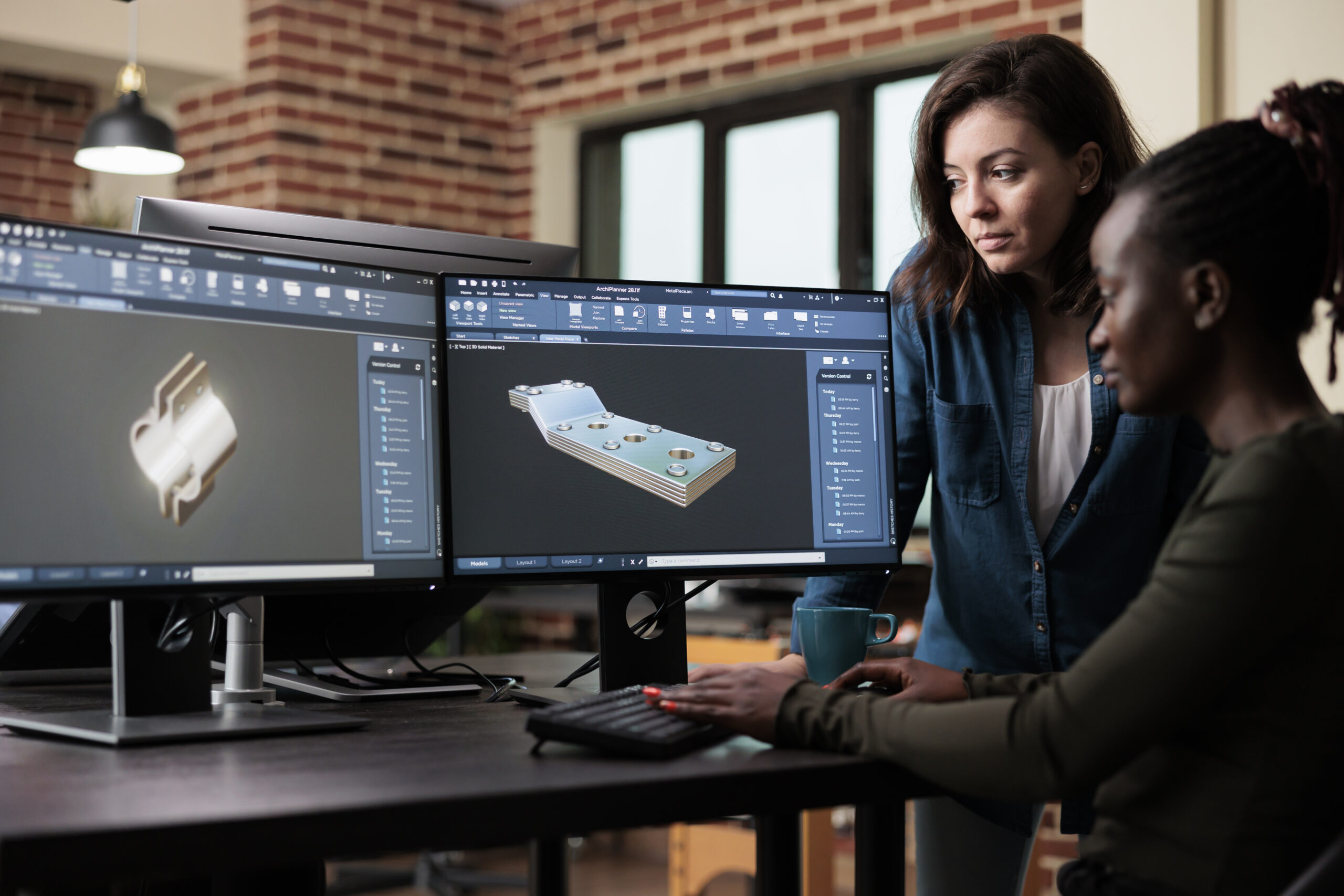

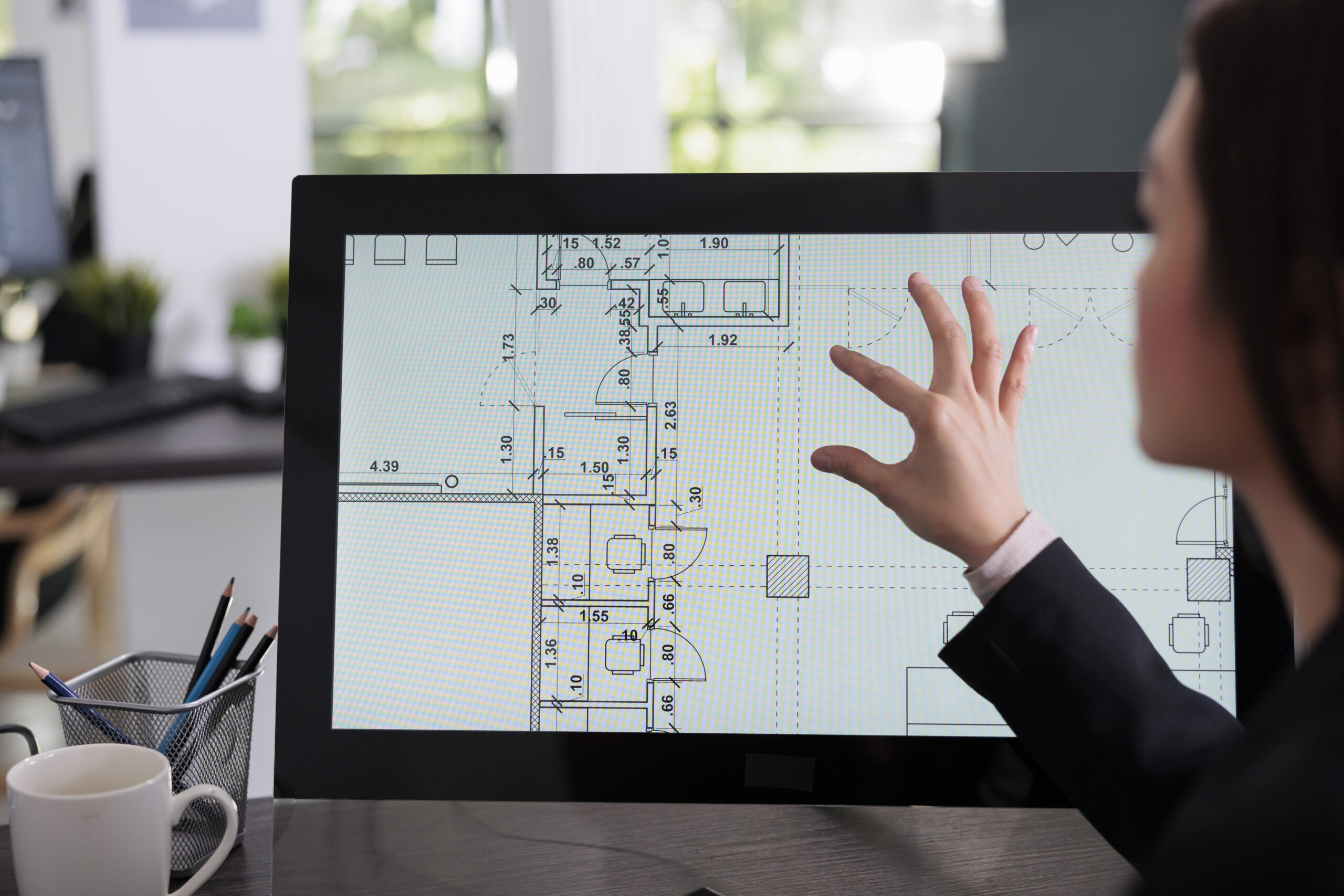

From Concept to Creation – Digitally Engineered Precision

Our expert team converts ideas, hand sketches, or existing parts into detailed, production-ready CAD models, ensuring flawless manufacturing.

- 2D & 3D CAD modeling using industry-leading software

- Reverse engineering of physical parts for replication or improvement

- Design optimization focused on manufacturing efficiency

- Tolerance and assembly fit analysis for perfect component integration

- Collaborative client feedback and iterative design updates

- CAD files compatible with CNC and other fabrication systems

- Simulation to minimize errors and reduce rework

- Digitizing legacy or obsolete parts for modern manufacturing

We bridge the gap between your ideas and the factory floor by delivering accurate, editable, and manufacturable CAD designs.

CAD Projects Delivered

Average Design Accuracy

Legacy Components Digitized

Frequently asked questions

Common questions about our design process and capabilities:

Yes, we use 3D scanning and measurement tools to accurately capture existing parts, allowing us to recreate or improve designs with precision.

We deliver CAD files in a variety of standard formats such as DWG, DXF, STEP, IGES, and STL, compatible with most CNC and manufacturing systems.

Absolutely. We work closely with clients throughout the design phase to incorporate feedback, update models, and ensure the final design meets all requirements before fabrication.